Mocked for lacking 800V fast charging? BYD: Not talking about it doesn't mean we don't have it.

In the past six months, 800V high-voltage fast charging has become the "hot cake" in the field of new energy vehicles. Many car manufacturers have listed ultra-high voltage fast charging as the technological high ground for market competition in the next phase. At this time, BYD, which has been silent, has led to endless speculation among those in the automotive industry:

While others are scrambling to deploy 800V, BYD is quiet. Have they taken the wrong technological direction? Or are they "inferior in technology" in this field?

In response to these questions, Ling Heping, the deputy dean of BYD's Automobile Research Institute, gave a special reply, and his response was quite unexpected.

I. Does BYD not have 800V? Ling Heping helplessly smiled bitterly.

On December 22nd of this year, the BYD Automobile Technology Communication Meeting was held in Shanghai. This meeting systematically reviewed BYD's technological layout in the field of charging.

During the meeting, the media specifically asked about the "standard" 800V high-voltage charging that other car companies promote, why doesn't BYD even mention it? The implication was clear: Have you not yet mastered this technology? In response to this question, Ling Heping helplessly smiled bitterly, and he said directly: Not promoting it does not mean we don't have it!

Advertisement

According to Ling Heping's introduction, since officially entering the new energy vehicle industry in 2008, BYD has always been working hard to tackle the charging problem. Why not promote 800V fast charging? Two reasons.

On the one hand, it is by no means "advanced" within BYD.

As early as 2015, BYD had mastered all aspects of 800V ultra-high voltage charging technology. To this day, BYD's technical team has even mastered higher voltage charging technology, and has successfully developed 1200V power components.Put yourself in their shoes: it's quite a challenge to ask a company that has reached the pinnacle of technology to turn back and boast about its outdated old technology at home. On the other hand, not emphasizing high-voltage charging is also related to the current industry environment.

According to data from the Ministry of Industry and Information Technology, as of November 2023, a total of 6.27 million new energy vehicle charging piles have been built in China. The number is not small, but it's important to note that supercharging piles supporting 300A only account for about 2% of the total number of charging piles. This means that the vast majority of current charging piles do not have the conditions to implement 800V high-voltage fast charging.

Reasonable scientific researchers know that whether a technology can be popularized depends not only on the superiority of the technology itself but also on whether the industry environment is ripe. Against the backdrop of unsupported charging piles, heavily promoting 800V fast charging technology has a bit of a "pie in the sky" implication.

In fact, it is precisely because of the full consideration of the construction of domestic charging piles that BYD has intentionally overlooked the promotion of high-voltage fast charging technology, instead providing car owners with a more down-to-earth charging solution: dual-gun supercharging.

Compared with high-voltage fast charging, what are the advantages of dual-gun supercharging? Let's take a look together.

II. Three major advantages, fully docking the pain points of new energy vehicle energy replenishment

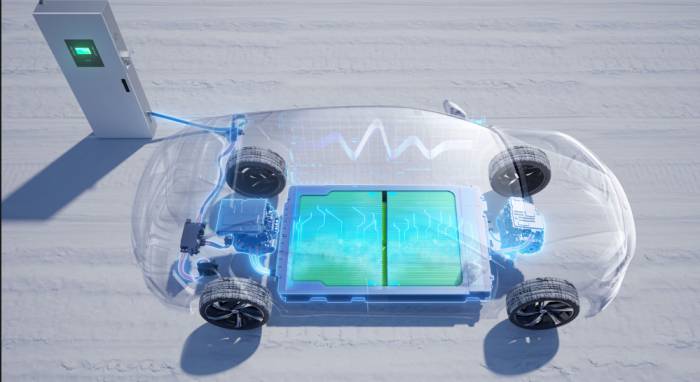

The so-called "dual-gun supercharging" is, as the name suggests, an energy replenishment system that is equipped with a charging circuit on both the left and right sides of the vehicle body. With the support of BYD's various "black technologies", dual-gun fast charging has the following three major advantages, each of which is a targeted solution to the current market's energy replenishment pain points.

1. Charging on both sides, fundamentally solving the difficulty of choosing piles, and alleviating slow charging

Equipping charging ports on both sides first solves the problem of choosing the position of the charging pile. From now on, car owners will no longer have to worry about the location of the charging pile. As long as there is an idle charging pile on either side, it can be directly used to replenish energy for the vehicle. If there are charging piles on both sides, it's even better. Charging simultaneously, the energy replenishment current is directly doubled, and the charging efficiency is greatly improved.Some may wonder, with single-sided charging of new energy vehicles, the bottom plate of the car is already hot to the touch. What if an additional charging circuit is added, leading to uncontrolled temperature increases? For this concern, BYD also has a follow-up strategy.

2. Composite Direct Cooling Technology, Effectively Avoiding Charging Thermal Runaway

To ensure the stability of dual-gun fast charging, BYD has exclusively developed composite direct cooling technology. This technological framework includes direct cooling plates laid on both the top and bottom, two sets of independent refrigerants, and also employs a compensatory flow channel design.

Internal testing has shown that this technology increases the battery cooling area by 100%, and the heat exchange capacity is significantly improved by more than 85%. Even with dual-gun charging, it can ensure that the battery temperature is always maintained within a safe range.

3. Intelligent Pulse Self-Heating, Charging Difficulties in Winter? Not an Issue

Lastly, addressing the issue of reduced charging efficiency in low-temperature environments, BYD has introduced a new active heating solution—Intelligent Pulse Heating.

Under the control of the electric drive multi-dimensional space control mechanism, the power battery can generate a frequency-controllable alternating current through an internal series-parallel sub-pack topology, thereby quickly raising the temperature of the battery cells. This is the basic principle of "pulse heating."

The application of this technology has increased the battery heating rate by more than 200%. Reflected in charging efficiency, extreme cold charging tests at minus 30 degrees Celsius have shown that the battery full charge time has been reduced by 30% compared to traditional heating solutions, ensuring the rapid charging and normal use of electric vehicles in the cold season.

III. Conclusion

Holding ultra-high voltage charging technology, yet focusing on promoting dual-gun supercharging. This strategic move, closely aligned with practicality, once again proves that when planning for the future, BYD always prioritizes "what the market needs" rather than "what I have, you use what."What is even more commendable is that BYD's dual-gun ultra-fast charging patent has been opened up to the entire industry. All related enterprises can apply this architecture for free, thereby better serving the public.

Respecting market needs and driving industry development—this kind of vision and responsibility is indeed worth learning from for many practitioners!

Leave A Comment